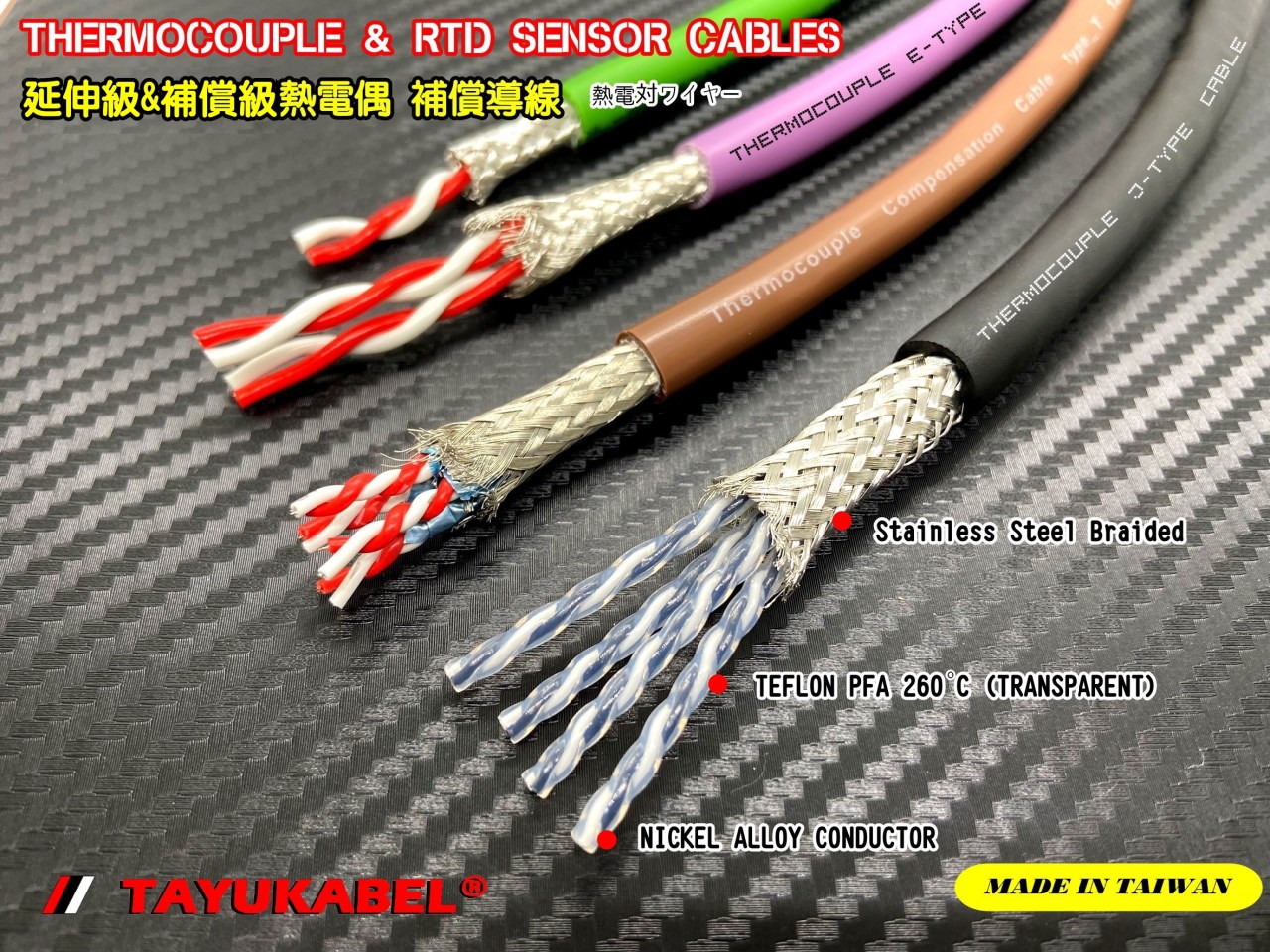

【The Best Solution of Thermocouple Cable】

【 Principle of Thermocouple 】

A thermocouple is composed of two wires made from dissimilar metals. These two wires are joined to form a temperature measurement junction. Each wire is made of a specific metal or metal alloy. For example, the positive (+) conductor of a type K thermocouple is made of a chromium/nickel alloy called chromel and the negative (-) conductor is made of an aluminum/nickel alloy called alumel. The wire used to make a thermocouple junction is called thermocouple wire.

.png)

【Various insulating materials and physical properties】

|

Material

|

Temp. Range

|

Flame Retardant

|

Abrasion resistance

|

Chemical Resistance

|

Moisture Resistance

|

Flexibility

|

|

PVC)

|

From -20°C to 105°C

|

Poor

|

Good

|

Good

|

Good

|

Excellent

|

|

(FEP)

|

From -100°C to 200°C

|

Good

|

Excellent

|

Excellent

|

Excellent

|

Good

|

|

(PFA)

|

From -267°C to 260°C

|

Good

|

Excellent

|

Excellent

|

Excellent

|

Good

|

|

KAPTON

|

From -267°C to 316°C

|

Good

|

Excellent

|

Good

|

Good

|

Good

|

|

Fiber Glass

|

From -100°C to 500°C

|

Excellent

|

Ordinary

|

Excellent

|

Poor

|

Ordinary

|

|

Fiber Glass II

|

From -100°C to 710°C

|

Excellent

|

Ordinary

|

Excellent

|

Poor

|

Ordinary

|

|

Ceramic fiber

|

From -100°C to 1200°C

|

Excellent

|

Poor

|

Ordinary

|

Poor

|

Ordinary

|

【Resistance Temperature Detectors (RTDs)】

There are other temperature measurement technologies than the thermocouple such as RTDs (resistance temperature detector). In applications with temperatures above 1,200° F (650° C), the thermocouple is used. At lower temperatures, RTDs are used for their simpler operation and greater sensitivity and stability. Thermocouples have a better response time. RTDs are special resistors whose resistance value changes with temperature in a known way. RTDs are connected to the temperature recording or process control instrumentation using an ordinary copper instrumentation cable. A thermocouple wire is not required to connect an RTD.

A typical RTD cable is a standard instrumentation cable in two, three, or four conductors or possibly groups of pairs/triads/quads depending on the type of RTD being used and a number of devices being monitored. Individual or overall shielding is often used for noise immunity.

RTD- 【 Compesation Grade 】

|

ANSI

Code

|

Thermocouple Grade

Jacket Color Identify

|

Positive

|

Negative

|

Temp. Range

|

|

J-TYPE

|

Brown

|

Pure Iron

|

Copper-nickel

|

-210℃~1200℃

|

|

K-TYPE

|

Brown

|

Nickel- Chromium

|

Nickel-Aluminum

|

-270℃~1372℃

|

|

T-TYPE

|

Brown

|

Pure Copper

|

Copper-nickel

|

-270℃~400℃

|

|

E-TYPE

|

Brown

|

Nickel- Chromium

|

Copper-nickel

|

-270℃~1000℃

|

RTD- 【 Extension Grade 】

|

ANSI

Code

|

Extension Grade

Jacket Color Identify

|

Positive

|

Negative

|

Temp. Range

|

|

J-TYPE

|

Black

|

Iron

|

Copper-nickel

|

-210℃~1200℃

|

|

K-TYPE

|

Yellow

|

Nickel- Chromium

|

Nickel-Aluminum

|

-270℃~1372℃

|

|

T-TYPE

|

Blue

|

Copper

|

Copper-nickel

|

-270℃~400℃

|

|

E-TYPE

|

Purple

|

Nickel- Chromium

|

Copper-nickel

|

-270℃~1000℃

|

.png)